DIY EV 3: GoWesty Hybrid Inspiration

The dilemma

It’s been hard to reason around the tradeoffs needed to convert the syncro to electric. On the one hand, I really want to roll along silently, with no engine noise, mile after mile. On the other hand, it is a big vehicle, and I probably wouldn’t be able to roll along for many miles before needing to recharge. And, since we use the bus in remote places, there would be nowhere to recharge at our destination.

I initially thought about converting the bus to pure electric by connecting the motor to the transmission, and putting in a mid-sized pack, say, 40kwh, to give me ~120km of range. This is sufficient for my daily needs, and, if we go on a road trip, I would need to bring some means of power generation - either a store-bought generator, or to make my own from a motorcycle engine coupled to my spare outlander motor.

Neither of these options seemed palatable to me. For one, they would be bulky - I’d probably have to take a trailer on the road. And my motor is quite small, so the extra weight of the trailer would seriously impact my continuous speed. Finally, all this stuff would be arranged in series. Energy would go like so:

Petrol -> Engine -> Motor -> Inverter -> DCHV Bus -> Inverter -> Motor -> Gearbox -> Wheels

If one of those failed, the chain would be broken, and I’d be stuck.

Another option I was considering was to leave the petrol engine in the back, connected to the gearbox, and to simply replace my front diff with the Outlander unit. This would mean I could drive electric with the one set of wheels, petrol with the other, and possibly some sort of hybrid arrangement, whereby the electric motor assists the petrol motor when needed.

In theory, all good, but I wasn’t sure if it would actually work. How would I deal with the gas pedal? Should it go to the petrol engine, or the motor, or both?

I found a journal article detailing a method of operating an electric motor in through-the-road parallel arrangement (that’s the official term for this sort of design) via a torque leveling algorithm that used a few simple data feeds from a petrol engine (see here), but I still wasn’t sure whether it would work in the wild.

GoWesty to the rescue

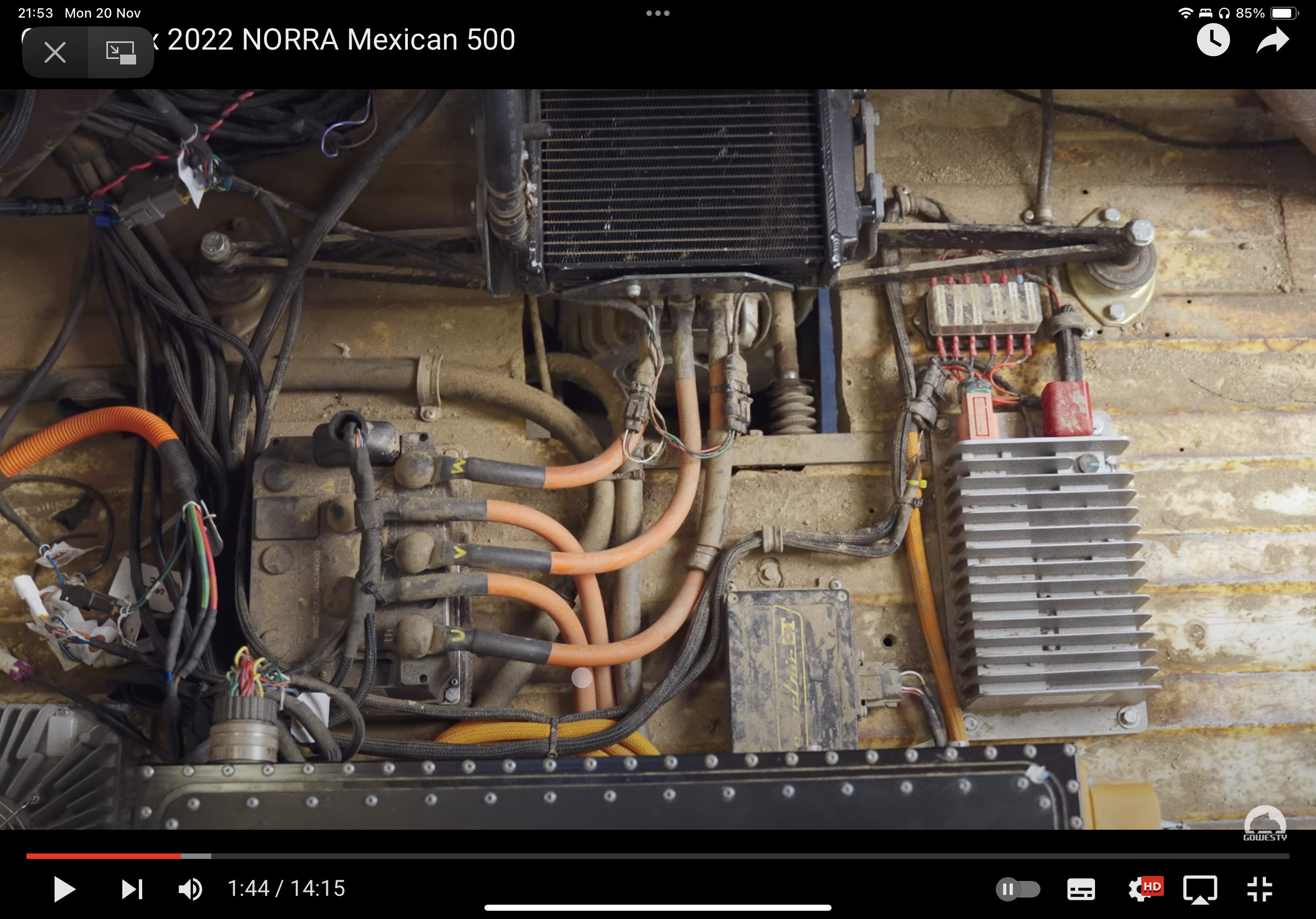

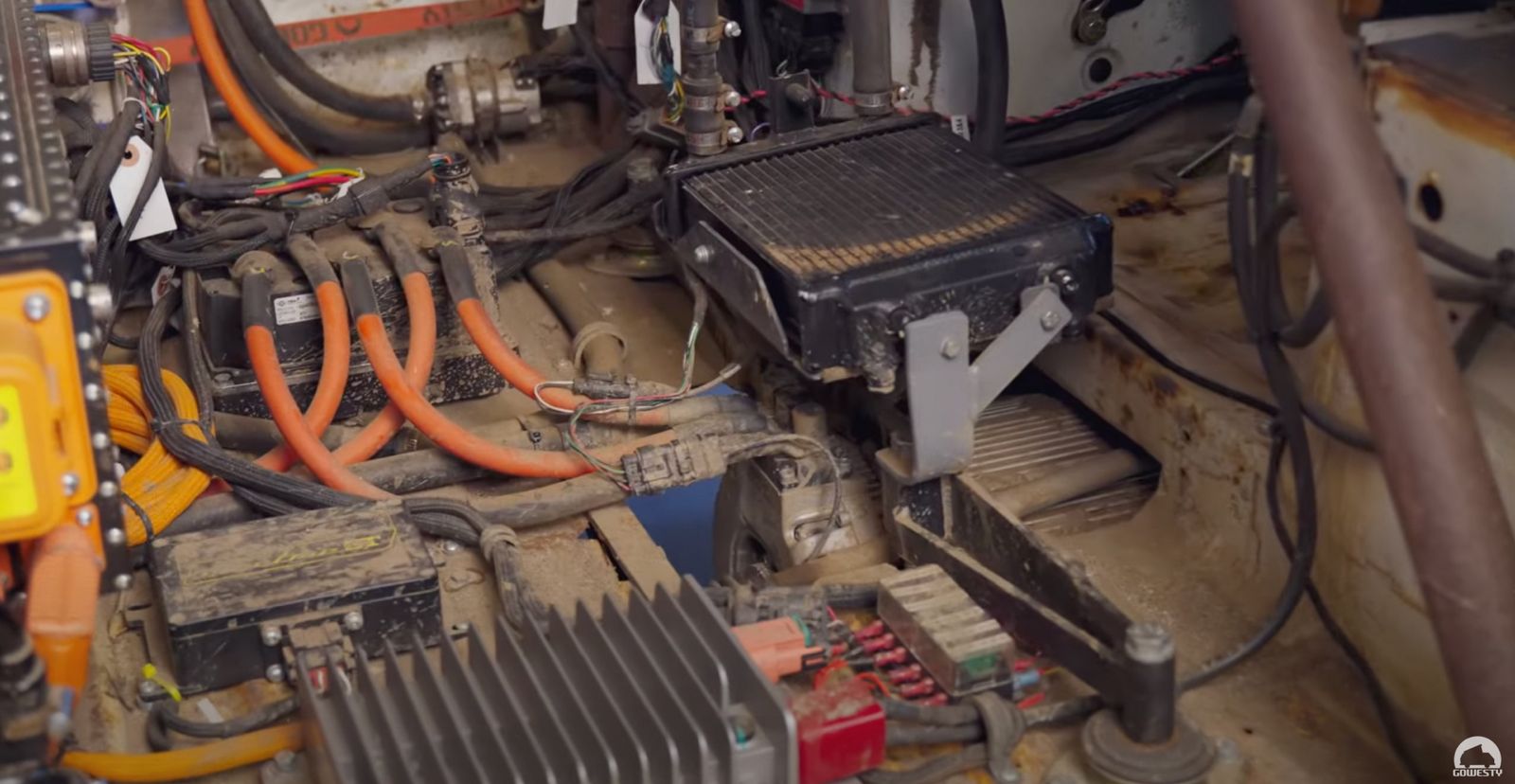

While researching something completely different, I stumbled upon a samba thread on the GoWesty Norra 500 2022 Syncro Hybrid. It turns out GoWesty implemented the exact design I was contemplating. And it seems like it worked great!

I googled about a bit more and found an interview, which I used to screenshot out some images of the actual bus.

While they did an amazing job proving out the concept, I can already see some improvements I could make over their implementation. They seem to have used a Hyper9 based system, which is quite expensive, and aircooled to boot. They also used a really big battery, which I don’t think is really necessary for a hybrid application. All in all, I think I have a good shot of building on their work to make something a bit more compact, cheap and integrated.

How does it work?

Basically, it looks like they have set up the electric motor controller to receive its torque request signal from a laptop / computer which calculates required electric torque based on input data from the petrol motors sensors. When the sensors indicate the engine is under load, the controller receives a signal for increased torque. When the sensors indicate the engine is under low load, the torque signal backs off, or, if it’s really low, requests negative torque (aka regen) to recharge the battery.

The net effect is that the petrol engine is always operating in a more optimal efficiency range, and the ’effective power’ to the wheels is doubled, because you’ve got the engine driving the back and the motor powering the front.

Mechanically, they decided to retain the front stock differential. They removed the viscous coupler housing and internals, which left a rather long pinion shaft sticking out of the diff. They cut the pinion shaft and fabricated a coupler that coupled the stubby pinion shaft to the motor shaft, and then fabbed an adapter plate the connect the Hyper9 motor to the front diff.

For my part, I am unsure whether that is mechanically simpler than just dropping the stock front diff and installing the outlander motor and diff as an integrated unit. Eyeballying the space, either option will result in a LOT of work.

Here are the screenshots I pulled from the youtube interview: