DIY EV 4: Power Steering Pump

Engines do more than just move a vehicle

One thing that it not obvious to a first time DIY EVer is that a conventional car engine actually does more than just move the wheels. It also -

- Provides vacuum for the brakes

- Provides pressure to the power steering system

- Provides 12v power to electric components

- Compresses air for the aircon system

- Provides heat for the cabin

- Cools itself by pumping heat from the engine to the radiator via water pipes

And probably a lot more on modern vehicles.

One needs to find solutions for each of these (now absent) functions. Because I’m working in a very incremental fashion, I figured I could try tackle some of these while the bus still has a running petrol engine in it.

First up was the power steering. The syncro came with factory power steering, which is pretty essential on an offroad vehicle. My power steering system is powered by the stock Golf 3 power steering pump, which, in a bus, sits at the very bottom of the engine, directly behind the exhaust muffler.

It is perfectly placed to catch stones while driving on gravel, and in our recent Namibia trip I lost 4 fan belts over the course of several days. As we got back to Cape Town, the pump started getting louder and louder, and it is currently in a failed state. So, perfect for a replacement, and I might as well go for an electrical unit and get one step closer to an EV conversion.

The Volvo Power Steering Pump

I selected the Volvo Hydraulic Electric power steering pump because it is cheap, available from salvage yards, and documented to work with minimal fuss. Here are some links that really helped me out while I was researching this:

- https://openinverter.org/wiki/Volvo_Power_Steering_Pump

- https://www.corral.net/threads/volvo-electric-power-steering-conversion-full-write-up.2499503/

The corral.net post showed that the pump could be used without an external controller (although one would be nice) - the pump falls back to running in permanent 75% failover mode. You have to wire it as follows:

From the thread:

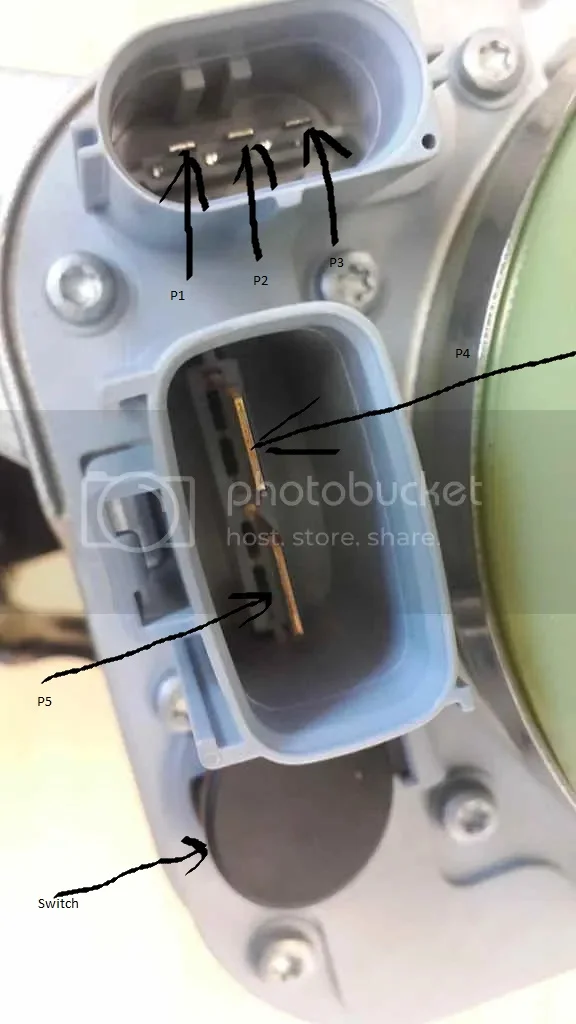

P5 is constant power. Use an appropriate gauge wire and a 40 AMP fuse. P4 is constant ground. Attach this to a good chassis ground.

P1 is the remote wire that will turn on the pump.

I found a Volvo breaker on Facebook Marketplace, drove out to Phillippi, and traded R2700 for a pump and high pressure hoses. When I finally got to hooking it up over the weekend, I found it was dead, so I had to drive back to the breaker and swap it for another one. The picture below shows what mine looks like.

Once I connected the cables as described above, there was a 3 second delay, then it spun up to 100%, before slowly slowing down to 75% over about 10 seconds. Then it held steady at 75% until I disconnected the ignition wire.

Success!

Since I had to get my steering rack rebuilt, I chucked the pump in the back, and got the power steering repair shop to install this pump and bypass the power steering pump on my engine.

Update: bus install

So the pump is in my bus. It sits where the old reservoir sat. It works pretty well, and I can’t hear it over the regular engine noise. Steering is a bit heavier, so I’d like to get a CAN controller for it from eBay ($45). I have a bit of anxiety about how much power it draws from the alternator. We’ll see how that goes - maybe I’ll need to upgrade the alternator.

I notice a pretty big difference in engine performance at really low revs, when turning. This makes sense, as there is no more parasitic draw from turning. Because I live in a hilly area, this is a pretty big win.

Update 2: GPS-based controller

I finally installed the GPS-based pump speed controller from Steering Electronics. Install is really easy, and takes about 40 min if you don’t mind calling ‘cable tie’ a tier-1 automotive component. How does it feel? Pretty good! When you are going slow, the pump works harder, so turning is easier. When you speed up, it slows down, and steering becomes more stiff. It really stabilizes the bus at speed, and makes the handling feel much more confident.

Do you need it? No. Would I recommend it? Definitely.